Offered on the UD campus during the first two weeks of July, the camps brought 42 students representing 24 middle and high schools in Delaware, Pennsylvania, New Jersey and Maryland to campus for a variety of demonstrations and hands-on activities.

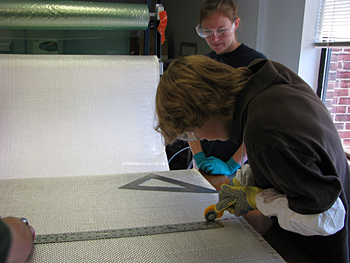

Heider, assistant director for technology at UD's Center for Composite Materials, led the students in fabricating composite panels using the vacuum-assisted resin transfer molding process and then testing them to failure the next day. “The kids were all excited about breaking the specimens,” he said.”

Garbini, lab coordinator in the Department of Materials Science and Engineering, used frozen fruits, flowers and rubber balls to show the students how liquid nitrogen is used in research to slow down the movement of molecules so that material structure can be studied and characterized. “The kids weren't paying much attention to me until I started breaking and crushing things,” he said. “Then they really got into it.”

But the engineering camps were as much about making things as about breaking them. The students had the opportunity to build bridges, solar cars and windmills, with competitions for each of these activities. “These projects are team-building exercises, as well as learning experiences,” said Kathy Werrell, assistant dean for engineering outreach, who organizes the camps.The students also learned about a variety of other engineering topics, including fuel cells, ocean engineering and materials processing. “We try to offer a lot of different activities throughout the week, so we can appeal to a variety of interests,” said Joe Tanner, engineering coordinator, who assists Werrell with the program.

Emily Andersen, seventh-grade daughter of Steve Andersen, CCM assistant director, welcomed the opportunity to learn more about what really goes on in the Composites Manufacturing Science Lab, where her father works. Emily, who is home-schooled and said she thinks she might want to be an engineer, said the coolest thing she learned was “how carbon fiber is stronger and more lightweight than steel.” She also really liked “working with the titanium.”

One activity that seemed to appeal to most of the participants, especially those like ninth-grader Samantha Garbini who enjoy hands-on projects, was the opportunity to become inventors. After a presentation early in the week by Werrell on preparing and conducting a market survey for invention ideas, the students worked in pairs or small groups to design a concept or device to solve a problem.

One creative group designed a “green” trailer for disaster victims, to be made entirely from reusable, recyclable or biodegradable materials. Other inventions included an impact-resistant egg carton, a convenient composter and a walking stick for a blind person--equipped with a talking GPS whose programming buttons were labeled in Braille. The students made posters or models of their inventions and explained them to guests at a fair on the last day of camp.

Caleb Boggia-Curles, a seventh grader who wants to be a mechanical engineer, said he enjoyed learning about the properties of polymers and working with titanium and electricity. “The camp was challenging, fun, educational and well-coordinated,” he said, “and I can't wait to take it again next year!”Article by Diane Kukich

Photos courtesy of Joe Tanner