Designing for health

Interdisciplinary projects yield new engineering designs for better diagnostics, treatment

10:27 a.m., Jan. 7, 2015--Dr. Freeze Grips, Playskin Air, Smart Boot and Active Hoof sound like the stuff of science fiction, but they’re actually the work of interdisciplinary senior design teams at the University of Delaware in a course taught by a team of mechanical and biomedical engineering professors.

Many of this year’s 20 interdisciplinary projects focused on solving health-related challenges.

Campus Stories

From graduates, faculty

Doctoral hooding

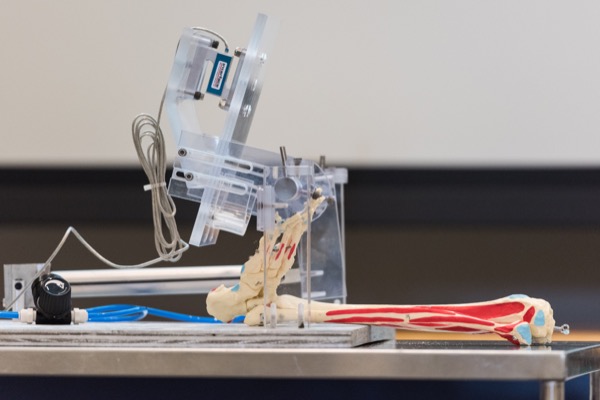

Devices ranged from a heart model and an efficiency tracker for stair climbing to a pediatric exoskeleton and an interactive play gym that senses muscle activity. Other devices will enable clinicians to remotely monitor a patient’s condition and to measure readiness to drive in patients recovering from lower limb orthopedic surgery.

Healthcare Theatre simulations

Four teams added to the suite of tools for increasing realism in UD’s Healthcare Theatre Program: SimuCath, a urinary catheter simulation; SimuThor, which guides post-op chest tube assessment and care; SimuShock, a defibrillation simulation; and SimuStick, which teaches proper intravenous needle insertion.

All of the devices are wearable, with sensory feedback built in for the actors playing the role of patients. Last year, teams created SimuTrach, which teaches proper tracheostomy care and suctioning, and VidaVest, for practicing CPR.

“We’re continuing to generate ideas for new simulation devices, and we hope to eventually market the entire suite as a family,” says Amy Cowperthwait, coordinator of the simulation lab in UD’s School of Nursing. “Using live actors and these simulation tools provides a superior learning experience for our students in a safe environment that doesn’t compromise quality of care.”

Liyan Wang, associate professor of mechanical engineering, worked with three of the Healthcare Theatre teams, including the group that developed SimuStick.

“They encountered a number of materials challenges in developing their product,” she says. “Twice, they struggled for a week and then came up with an innovative solution. They did a great job, and now they’re going to publish their approach.”

Supporting surgery and workplace ergonomics

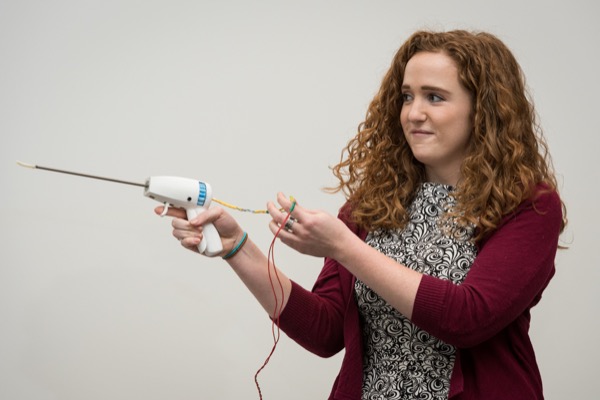

One team created a minimally invasive vessel-sealing tool that incorporates an attachable extendable shaft and interchangeable tip sizes for use in laparascopic surgery. With Dr. Joseph Bennett, a surgical oncologist at Christiana Care, as one of their advisers, the team had an inside track to the exacting requirements for the device.

Bennett met with the students every week to provide feedback, and at the end of the 14-week semester, he was more than satisfied with the results of the project.

“It went great,” he said. “We accomplished even more than I expected, and now we’re looking into patenting the concept and commercializing the device.”

Other projects were aimed at solving workplace ergonomic issues. One team worked with VWR International to create Uncap’n It, a machine that caps and uncaps sterile vials, while another group collaborated with W.L. Gore & Associates to develop tooling for suture manufacture. The purpose of both devices is to eliminate the need for injury-producing repetitive movement on the part of lab technicians.

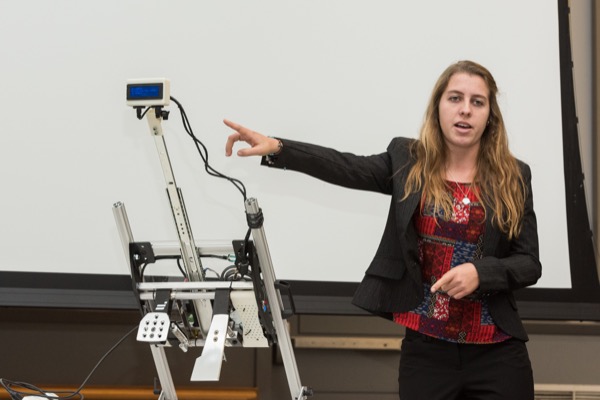

“Most of the teams on these projects are actually designing for or working with human subjects,” says Dustyn Roberts, assistant professor of instruction in mechanical engineering. “One team even had their protocol approved by the IRB [Institutional Review Board] early in the semester, and they were able to run 30 subjects through their experimental protocol this fall.”

“Engineers in general don’t get experience testing devices on real people until much later in their careers, if at all,” she adds. “At larger companies or labs, the separation between engineers and end users is much greater than it is with our students.”

Designs for everyone

Not all of the patients who stand to benefit from the student designs are human.

One team developed a device that can simulate the natural walking deformation of a horse hoof in order to prevent laminitis, a condition that claimed the life of famed thoroughbred racehorse Barbaro in 2007. The students worked with veterinary specialists at the University of Pennsylvania New Bolton Center on Active Hoof, which is intended to be worn by horses with restricted movement due to injury.

Other projects in the interdisciplinary program included hands-on K-12 workshops in orthopedics, a magnet-based socket system for a prosthesis, a next-generation Quadcrew adaptive rower, an MRI-compatible dynamometer, and a magnetic suspension system for lower limb amputees that enables the user to attach and remove a prosthesis.

Collaborators represented a number of departments and schools across campus, including kinesiology and applied physiology, physical therapy, education, and fashion and apparel studies.

“It’s been wonderful working with engineering and fashion on our pediatric mobility projects,” says Michele Lobo, assistant professor of physical therapy. “Our main goal is to get kids moving with solutions that are guided by kids so they appeal to kids.”

The latest in her “FUNctional Fashion” line is a garment that children with arm movement impairments can inflate and deflate to assist them in moving their arms so they can better explore, play and learn.”

Themes running across the health-related projects included safety, durability, comfort, cost-effectiveness, ease of use, and, for the simulations, realism.

“It’s really quite amazing what our students are able to accomplish over the course of a semester,” says Jenni Buckley, assistant professor of mechanical engineering. “We’ve had sponsors come back to us and say that their teams have accomplished in four months what it takes them years to do. That’s what we like to hear. We want our students to get their ideas out there.”

Financial support for the projects was provided by industry, the College of Health Sciences and the Office of Economic Innovation and Partnerships.

Clinton Global Initiative University

Two of the students who worked on the SimuCath project — Bimal Amin, a senior in biomedical engineering, and Taylor Boyle, a senior in biomedical engineering — have been accepted to the eighth annual Clinton Global Initiative University, which will take place from March 6-8 at the University of Miami in Coral Gables, Florida.

The meeting will bring together more than 1,000 innovative student leaders to make commitments to action in CGI U’s five focus areas: education, environment and climate change, peace and human rights, poverty alleviation, and public health.

Article by Diane Kukich

Photos by Evan Krape