|

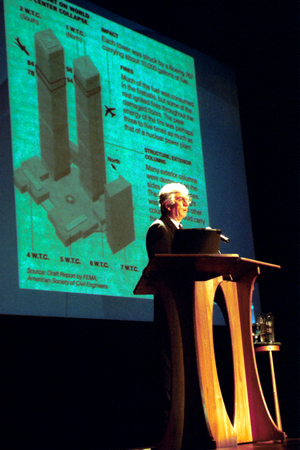

World-renowned structural engineer Charles H. Thornton of the New York-based Thornton-Tomasetti Group discussed the collapse of the World Trade Center to an audience of more than 200 faculty, students, alumni and community members on Tuesday, April 9, in Mitchell Hall. World-renowned structural engineer Charles H. Thornton of the New York-based Thornton-Tomasetti Group discussed the collapse of the World Trade Center to an audience of more than 200 faculty, students, alumni and community members on Tuesday, April 9, in Mitchell Hall.

The event was the first in the Department of Civil and Environmental Engineering Distinguished Lecture Series.

Thornton was introduced by Arnold Kerr, UD professor of civil engineering, who had taught at New York University when Thornton was a graduate student there in the 1960s. “Kerr was the best professor I had at NYU–he had a profound influence on me,” Thornton said. “He taught me that the best approach for engineers is to formulate problems and get mathematicians to solve them.”

As a structural engineer, Thornton said he was just as stunned as the general public when he saw the two buildings collapse. However, even though he could not have predicted the catastrophic failure of the towers, he admitted that the terrorists could not have chosen better buildings to attack.

He explained that the towers were innovative and built according to code, but the core was constructed to withstand only gravity and the outside to resist only wind. “The towers had good vertical capacity,” he said, “but little ability to resist horizontal forces. The floors didn’t transmit any load–they were basically just diaphragms to ‘keep the square square.’”

Thornton-Tomasetti experienced a massive deployment of staff the day after the disaster, when the firm was hired by the city to aid in the response effort. When the arranged transportation to take staff members from their office to the site failed to show up, the engineers walked the four miles through smoke, concrete dust,and a chilling absence of the normal city bustle. The company has had staff there around the clock ever since.

“The psychological trauma they’ve been through is unimaginable,” Thornton said. “They’ve seen things people should never see.”

Thornton attached some numbers to the devastation: Each floor of the two towers was an acre, adding up to 110 vertical acres apiece. Compressed, however, the rubble from the two buildings would fit into a surprisingly modest-sized hole–about 65 feet by 500 feet by 1,000 feet. In the six months since the collapse, some 1.2 million tons of debris have been removed from the site.

Some debris, however, has proved useful. While the concrete in the buildings was almost totally pulverized–resulting in the six to eight inches of dust that settled on everything in the vicinity of the disaster–the steel columns survived almost intact. They have since been used in the cleanup effort to shore up sections in danger of collapse during the immediate recovery stage and to provide support for bulldozers and cranes involved in the cleanup.

Thornton predicts greater future collaboration among architects, structural engineers, fire engineers, sociologists and disaster managers. He also said he thinks there will be a major re-evaluation of fireproofing techniques and requirements. Greater consideration will be given to design for progressive collapse, which in his opinion, does not add significantly to cost.

“It’s an unfortunate fact of life that we get to do the really sophisticated engineering analysis after the fact when we’re called in to evaluate a collapse,” Thornton said. “This is the stuff that we’d like to be able to do in designing the building up front. The good news is that we pass along what we learn to the design team, so we can at least have an affect on future design.”

Story by Diane Kukich

April 10, 2002

|