|

|

Expedition

Expedition | People

|

Log - July-27-2003

by Robert McCarthy

Previous | Next

| The sound of water |

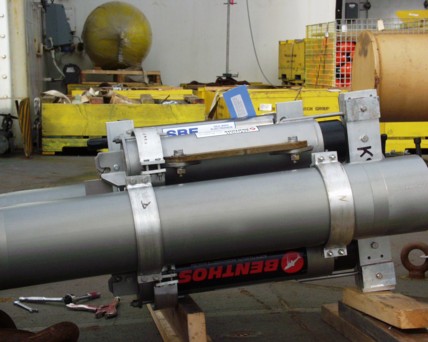

Fig 1: Acoustic releases ready for testing on the rosette. |

I was talking with Dave Huntley this morning, about the instrumentation that will be thrown overboard in the hopes of recovery in 2 to 3 years. However, it is not as haphazard as that might sound (sound being the operative word here). The ships position is precisely known, and the instruments are held firmly to the ocean bottom with very large weights. The instruments are then tethered to this weight by mooring lines, which are kept taught by subsurface floats. This is so ships don't run into them or get dragged or knocked around by icebergs. So the question is, how do they hope to recover them? Well, they purchased acoustic releases that will be attached to the large weight on the bottom. One release costs about $14,000 dollars, and they bought 36 of them. But that's not all. They also had to buy a deck box that will trigger the release mechanism, and that's another $10,000. So why pay so much? To make sure you get back all 26 of the bottom mounted Acoustic Doppler Current Profilers (ADCP), which costs $60,000 each and that records all of the current data that your research is hinged upon. These costs are just a part of the proposed study (acquiring ship time, crew, scientists, and other equipment related to the piston coring operation and water testing), so you can see how much money is being spent on this research. |

| The engineers at the factory must thoroughly test their designs. The deep releases are tested down to 2000 meters, which is about 200 atmospheres of pressure. The housing must be able to withstand that much pressure without leaking, plus the mechanism to open the release has to function at that pressure too. Also, the materials have to be corrosion resistant, so that the moving mechanisms don't corrode and release before requested. They contain alkaline batteries that are designed for about 2 years of life in warm water. These were adapted to sample intermittingly to extend the battery life to about 3 years in this environment. The signal to trigger release can be sent from as far away as 5 km. So if the water depth is 2 km, conceivably the ship could be 4.6 km away from the unit. (The 5 km being the hypotenuse of the right triangle with sides 2 km and 4.6 km.) The releases weigh about 44 lbs in air, and about 28 lbs in seawater. Thus the buoyant force is roughly 16 lbs. (Archimedes principle again.) |

Fig 2: The transducer, which is lowered into the water and sends the signal down to the release to trigger. This device also receives the return signal from the release. |

Fig 3: The deck box, which connects to the transducer, allows the desired frequency to be transmitted. |

Before they just through them overboard, they must first test them to see if they are working correctly. While we are in Baffin Bay taking CTD casts to sample the water, the mooring crew is busily designing ways to test the releases. They have attached the releases to a rosette (See fig 1), and tried to trigger them from the ship. This is a vertical test, because the release is directly below the ship on the rosette, and the transducer (the microphone/speaker) is also directly below the ship. Upon testing the releases this way, two were found to fail. Finding this out now was extremely important, since they realized that the transducer was probably too shallow and that they were experiencing a multipath interference problem. The signal to release was arriving just ahead of the same signal that reflected off the underside of the ship's hull and essentially told the release signal to be ignored. So by lowering the transducer 7 or more meters, they hope to solve that problem. |

| Also, Dave Huntley wants to test the range of the signal in a horizontal direction. This will be done by lowering the releases on the rosette again, but this time Dave will take the deck box with him on a small boat. Thus he'll send the trigger sound from a horizontal distance, and when they pull up the rosette, they'll be able to see which ones triggered. These trouble-shooting procedures are extremely beneficial, since you're always thinking of how things can go wrong and how you can do your best to assure success. The transducer (See fig 2) sends an acoustic signal (sound) at a frequency of between 9 and 13 KHz, in 1/2 KHz increments excluding 12 KHz. A hertz (Hz) is a cycle per second, and the 12 KHz band is reserved for the return signal to the deck box (See fig 3). So the deck box sends a signal, say 9 KHz, to the release, and after the release lets go of the anchor, it sends the 12 KHz signal back to the deck box signifying that it received the original signal and done its job. Since these are sound signals (pings) they travel at the speed of sound in seawater. This is about 1500 m/s, which is over 4 times the speed of sound in air. The speed of sound is greater in seawater than in air, since the particle-to-particle collision that transfers the energy happens faster in the denser medium. So the time it takes for the signal to hit the release, register and open, send the return signal, and finally hear the confirmation signal is only about 3 seconds. If you don't hear the return confirmation signal, you try again, and again, and again. If it doesn't release, they'll have to grapple for them, in which they lower a large grappling hook to the bottom, and have the ship track a circle around the mooring location, and as the ship steams away, you hope you catch it. However, this procedure is very time consuming, and you might damage the instruments. So on the very deep casts, the scientists designed a double acoustic release (See fig 4), whereby if one fails, the other might save the day. Again, that's another $14,000 but their design allows for recovery of both releases which can be reused on a later cruise. Better safe than sorry. All I can say is keep your fingers crossed! |

Fig 4: The mooring starting to take shape. The left side of this picture will connect to the bottom weight. Notice the release on top and on the underside, just in case. |

|